craftsmanship, reliability, precision and quality!

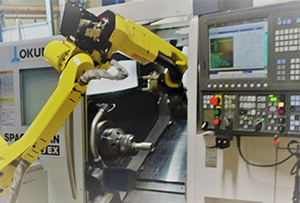

Nossin Fijnmechanische Industrie stands for craftsmanship, reliability, precision and quality. By combining these attributes with our ultramodern machinery and 24-hour production, Nossin Fijnmechanische Industrie can guarantee that we deliver according to your requirements.

Nossin FMI produces and assembles complex fine-mechanical components with a repetitive character against the right price/quality ratios and with a guaranteed precision. Nossin FMI delivers in accordance with the terms and conditions of the Koninklijke Metaalunie, is a member of the Mikrocentrum High-Tech Platform and of the Dutch Precision Technology Association.

OUR VIEW ON QUALITY

You can count on Nossin FMI to deliver high-quality, fine-mechanical components on time against the right cost price. Nossin can do this thanks to its ultramodern machinery, superb specialists, a conditioned production environment and the full-service production process, in which precision products are our hallmark.

Belangrijke peilers zijn nauwkeurig gemeten producten.

CERTIFIED

Nossin FMI has been ISO certified since 1993. The company has won various quality prizes. For example, in 2000 Philips Components proclaimed us the Best Equipment Manufacturer and in 2009 Nossin FMI received the Best Cost Supplier Award from trade journal Link.

History

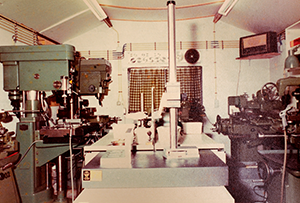

Nossin Fijnmechanische Industrie is a dynamic company with an established history. Nossin FMI has been active in the metal processing market since 1978. Today’s Nossin Fijnmechanische Industrie is the result of several important steps in the company’s history.

Company profile

Nossin Fijnmechanische Industrie produces complex fine-mechanical components with a guaranteed high level of precision, in all types of steel and non-ferrous metals. It is specialised in the machining of aluminium products. Nossin FMI also has considerable experience in the assembly of components. It can therefore assemble the components produced into modules.

Nossin FMI works for clients in various industrial sectors, such as machine and equipment construction, the semiconductor industry, the medical and laboratory technology industry, and the electrotechnical and power industries. Nossin FMI also manufactures components for measurement and monitoring equipment.

Thanks to the short lines of communication between Nossin FMI’s specialists we can work effectively and efficiently each day, 24 hours per day and 6 days per week. The result: an optimum process/quality ratio.

1978

1978  1980

1980  1985

1985  1987

1987  1999/2000

1999/2000  2004

2004  2009

2009  2010 / 2011

2010 / 2011  2016

2016  2017

2017  2018

2018